Publications from DIMES

-

Hack E, Luan L, Crosbie L et al. A Digital Image Correlation (DIC) prototype system for crack propagation monitoring in aircraft assemblies [version 1; peer review: awaiting peer review]. Open Res Europe 2022, 2:82 (https://doi.org/10.12688/openreseurope.14599.1)Hack E, Luan L, Crosbie L et al. A Digital Image Correlation (DIC) prototype system for crack propagation monitoring in aircraft assemblies [version 1; peer review: awaiting peer review]. Open Res Europe 2022, 2:82 (https://doi.org/10.12688/openreseurope.14599.1)

Hack E, Furrer R, Middleton C, Lambert P, Greene RJ, Kupferschmid A, Harris L, and Patterson EA, Simultaneous application of two thermal lock-in techniques in fatigue testing of CFRP aircraft panels, ASNT 17th International Symposium on Non-Destructive Characterization of Materials, Dubendorf, CH, August 16, 2023

-

Middleton C, Lambert P, Amjad K, Greene RJ, Kupferschmid A, Hack E, Harris L, and Patterson EA, Application of a low-cost Structural Health Monitoring system to full-scale aerospace testing, ETTC’23, European Test and Telemetry Conference, Toulouse, FR, June 14, 2023

-

Amjad K, Lambert P, Middleton CA, Greene RJ, Patterson EA, A thermal emissions-based real-time monitoring system for in situ detection of fatigue cracks, Proc. R. Soc. A 478: 20210796, 2022

-

Hack E, Luan L, Crosbie L and Michel S, A Digital Image Correlation (DIC) prototype system for crack propagation monitoring in aircraft assemblies, Open Res Europe 2:82, 2022

-

Amjad K, Lambert P, Middleton CA, Greene RJ and Patterson EA, Towards low-cost condition monitoring for crack detection based on thermal emissions, BSSM International Conference on Experimental Mechanics, Oxford, UK, 07-09 Sep 2021

-

Middleton C, Lambert P, Greene RJ, Kupferschmid A, Hack E, Michel S, Harris L, Siebert T and Patterson EA, Using COTS technology for Structural Health Monitoring in airframes during large-scale testing, ETTC’21, European Test and Telemetry Conference, June 15, 2021

-

Patterson EA, Engineers partner in `Smarter Testing’ project for aerospace sector, University of Liverpool News, April 21, 2021

-

Brunner AJ, Hack E, Patterson EA, Greene RJ, Crosbie L, Komplementäre Schallemissionsüberwachung quasistatischer Belastungsversuche an einem A320 Flugzeugflügel im Rahmen des Horizon 2020 EU-Projekts DIMES, Schall 21, DGZfP-Berichtsband BB 175, February 25, 2021

- Bucher R, DIMES - Development of Integrated Measurement Systems, Pool Meeting, Empa, Dubendorf, November 17, 2020

-

Luan L, Crosbie L, Greene RJ, Hack E, Lambert P, Michel S., Middleton CA and Patterson EA, A prototype of a DIC System for potential Structural Health Monitoring (SHM) applications, iDICs, Nantes (virtual), October 19-22, 2020

-

Lambert P, Furrer R, Hack E, Patterson EA, Low-cost Lock In Thermoelastic Stress Analysis, iDICs, Nantes (virtual), October 19-22, 2020

-

Patterson EA, DIMES tests innovative monitoring system for next-gen aircraft, Clean Sky News, June 8, 2020

-

Weihrauch M, Middleton CA, Greene RJ and Patterson EA, Low-Cost Thermoelastic Stress Analysis, SEM Annual Conference, Reno (NV), June 3-5, 2019

Blog posts

Taking an aircraft’s temperature as a health check

The title of this post is the title of a talk that I will deliver during the Pint of Science Festival in Liverpool later this month. ... This year I am moving up the size scale and from biomedical engineering to aerospace engineering to talk about condition monitoring in aircraft structures based on our recent research in the INSTRUCTIVE [see 'INSTRUCTIVE final reckoning' on January 9, 2019] and DIMES [see 'Our last DIMES' on September 22, 2021] projects. I am going describe how we have reduced the size and cost of infrared instrumentation for monitoring damage propagation in aircraft structures while at the same time increasing the resolution so that we can detect 1 mm increments in crack growth in metals and 6 mm diameter indications of damage in composite materials. ...

This blog post appeared on May 10th, 2023, on realizeengineering.blog

Seeing small changes is a big achievement

Some years ago I wrote with great excitement about publishing a paper in Royal Society Open Science [see ‘Press release!‘ on November 15th, 2017]. This has become a routine event; however, the excitement returned earlier this month when we had a paper published in the Proceedings of Royal Society of London on ‘A thermal emissions-based real-time monitoring system for in situ detection of cracks’. ... The device detects the changes in the temperature distribution over the surface of the metal caused by the propagation of a crack due to repeated loading of the metal. It is based on the principles of thermoelastic stress analysis ...

This blog post appeared on October 26th, 2022, on realizeengineering.blog

Too much of a good thing?

I wrote a couple of weeks ago about ‘Our last DIMES’ meetings. They were hybrid meetings with about half the participants attending in person and the remainder on-line. ... One of our first steps was to re-equip our meeting rooms with higher quality video conferencing facilities ... If you have never been present during a wing-bend test or a fatigue test on a large composite panel then you might find these clips interesting (see also the video of ‘Noisy progressive failure of a composite panel’ ). We also produced an introductory video for the DIMES project which was to be first in a series of video shorts but the pandemic intervened ...

For more short videos from our earlier projects see ‘Archive video footage from EU projects’ on June 5th, 2019.

This blog post appeared on October 6th, 2021, on realizeengineering.blog

Our last DIMES

Thirty-three months ago (see ‘Finding DIMES‘ on February 6th, 2019) we set off at a gallop ‘to develop and demonstrate an automated measurement system that integrates a range of measurement approaches to enable damage and cracks to be detected and monitored as they originate at multi-material interfaces in an aircraft assembly’. ... Two weeks ago, we held our final review meeting. ... Our innovative technology allows condition-led monitoring based on automated damage detection and enables ground tests on aircraft structures to be run 24/7 saving about 3 months on each year-long test.

This blog post appeared on September 22nd, 2021, on realizeengineering.blogNoisy progressive failure of a composite panel

Composite materials have revolutionized many fields of engineering by providing lightweight strong components whose internal structure can be tailored to optimise their load-bearing capabilities. ... Last month, we completed a further round of tests at Empa to demonstrate the system’s capabilities on composite structures which have been tested almost to destruction. ... Watch and listen to this short video to see and hear the material being torn apart – ignore the loud creaking and groaning from the test rig, it’s the quieter sound like dead leaves being swept up.

This blog post appeared on June 30th, 2021, on realizeengineering.blog

An upside to lockdown

While pandemic lockdowns and travel bans are having a severe impact on spontaneity and creativity in research, they have induced a high level of ingenuity to achieve the final objective of the DIMES project, which is to conduct prototype demonstrations and evaluation tests of the DIMES integrated measurement system. We have gone beyond the project brief by developing a remote installation system that allows local engineers at a test site to successfully set-up and run our measurement system. This has saved thousands of airmiles and several tonnes of CO2 emissions ... We are about to stretch our capabilities further by conducting a remote installation and evaluation test during a full-scale aircraft test at the Aerospace Research Centre of the National Research Council Canada in Ottawa, Canada. ...

This blog post appeared on April 14th, 2021, on realizeengineering.blogOut of the valley of death into a hype cycle?

Most valued player performs remote installation

My Engineering Day

Turning the screw in dentistry

Condition-monitoring using infrared imaging

When seeing nothing is a success

Same problems in a different language

... My research group is working on how we demonstrate the fidelity of predictions from models, how we establish trust in both predictions from computational models and measurements from experiments that are often also ‘models’ of the real world. The issues are similar whether we are considering the structural performance of aircraft [as in DIMES], the impact of agro-chemicals, or the performance of fusion energy and the impact of a geological disposal site.... This blog post appeared on October30th, 2019, on realizeengineering.blog

Joining the dots

Finding DIMES

Project Overview

Welcome to DIMES

DIMES was an Innovation Action within the European Commission's Horizon 2020 Clean Sky 2 program under Grant Agreement No. 820951.

This website reflects only the author's view and the Commission is not responsible for any use that may be made of the information it contains.

Our team involved Airbus Operations SAS ( Topic Manager) as well as University of Liverpool (Coordinator), Strain Solutions Ltd. (Technical Coordinator), Empa (Beneficiary) and Dantec Dynamics GmbH ( Beneficiary).

The aim of the project was to develop advanced integrated testing methods that have the capability to detect a crack or delamination in a metallic or composite structure and have the potential to be deployed as part of an on-board structural health monitoring system for passenger aircraft.

Find here an introductory video for DIMES, while the CORDIS website has a Results in Brief article on DIMES.

Clean Sky 2 Joint Undertaking

Clean Sky is the largest European research programme developing innovative, cutting-edge technology aimed at reducing CO2 gas emissions and noise levels produced by aircraft. Funded by the EU’s Horizon 2020 programme, Clean Sky contributes to strengthening European aero-industry collaboration, global leadership and competitiveness.

The DIMES project has been high-lighted on Clean Sky News.

Ongoing travel restrictions prevented the DIMES team from visiting Toulouse for deploying the measurement system on a cockpit test. Instead, the system was shipped to Airbus, and the Topic Manager has commissioned it under remote guidance by the team.

Project Chronology

| 18-19 Nov 2020 |

24m Meeting online Final results of the wing test at Empa were presented, and the panel test bench design was presented. Status updates of the commissioning of the DIMES system on a cockpit and full wing test at Toulouse and Filton, respectively, were given. |

|

| 15 Oct 2020 |

DIMES Installation Ongoing travel restrictions prevented the DIMES team from visiting Toulouse for deploying the measurement system on a cockpit test. Instead, the system was shipped to Airbus, and the Topic Manager has commissioned it under remote guidance by the team. |

|

| 17-18 Jun 2020 |

18m Meeting online Results on crack initiation and the further testing procedure on the wing test bench at Empa were discussed. System improvements were agreeed, and commissioning of the DIMES system on a cockpit and full wing test at Toulouse anfd Filton, respectively, was planned. |

|

| 26-28 Nov 2019 |

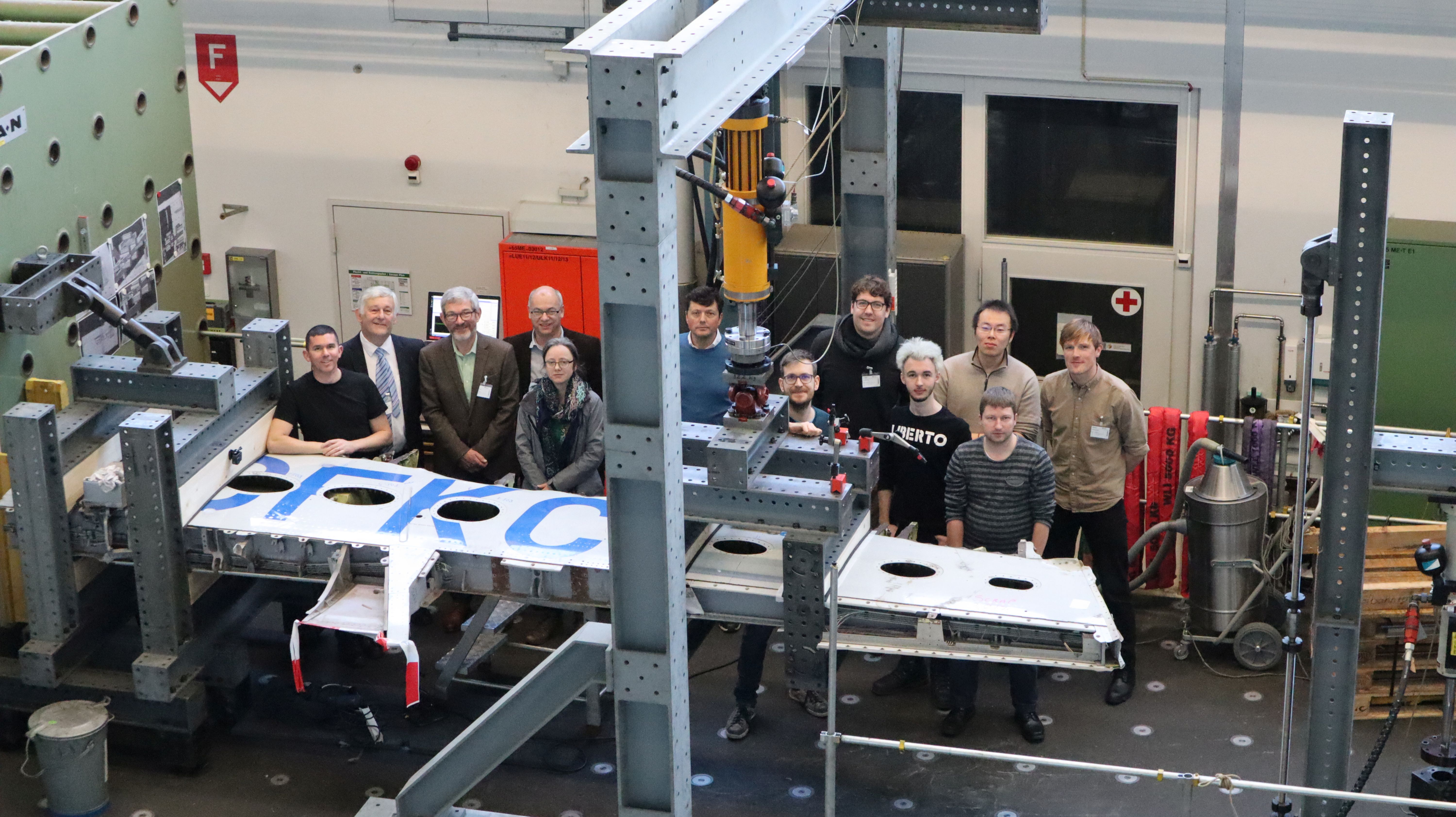

12m Meeting in Switzerland During the 12m meeting the DIMES team gathered around the test bench at Empa. The wing box will be loaded in a three point arrangement with the wing tip being deflected. The DIMES system will be placed into the bays through the access holes visible on the wing surface in the picture. |

|

| 26-27 June 2019 |

6m Meeting in London After a visit to Bristol to discuss test article options, the 6m meeting was held in London. A Milestone, the Preliminary design review, was successfully achieved. A decision was taken to use part of an A320 wing as test article for the test bench to be designed and implemented at Empa. |

|

|

20 Feb 2019 |

Brainstrom Meetings at Airbus, Toulouse Two brainstorm meetings were held to develop the concept for the DIMES integrated system. While the first meeting focused on combinations of measurement technology, the second was about implementing the sensors and developing an overall concept for data and power management as well as system control. |

|

| 14-16 Jan 2019 |

Kick Off Meeting in Liverpool Partners presented their organisation and people participating in the project. The Topic Manager provided an overview of Airbus. There was a discussion about the technology, the test article and their relationship to the DIMES work packages. |

|

| 1 Jan 2019 | Official project start date |